Prosthetic Socket Systems at Orthotics Limited

Comfort Changes Everything

With the right socket, life opens back up. You stop surviving and start thriving.

Why Choose Orthotics Limited for Socket Systems?

With over 40 years of socket fitting experience, we've solved challenges that other prosthetists couldn't. Our team specializes in complex cases and delivers results faster than facilities that outsource fabrication.

Custom-Engineered for Your Body

Every residual limb is different. We use 3D scanning technology and advanced materials to create sockets precisely engineered for your anatomy, activity level, and lifestyle needs.

On-Site Fabrication

We manufacture your socket right here in our labs. Direct socket systems are ready the same day. Custom sockets typically take less than a week. No shipping delays or communication gaps with external fabricators.

Technology That Adapts

From adjustable systems that compensate for daily volume changes to vacuum technology that promotes circulation, we use the latest innovations to keep you comfortable all day long.

Expert Problem-Solving

Short limbs, bony prominences, irregular shapes, extensive scarring; we've handled them all. Our prosthetists have the experience to solve fitting challenges others consider impossible.

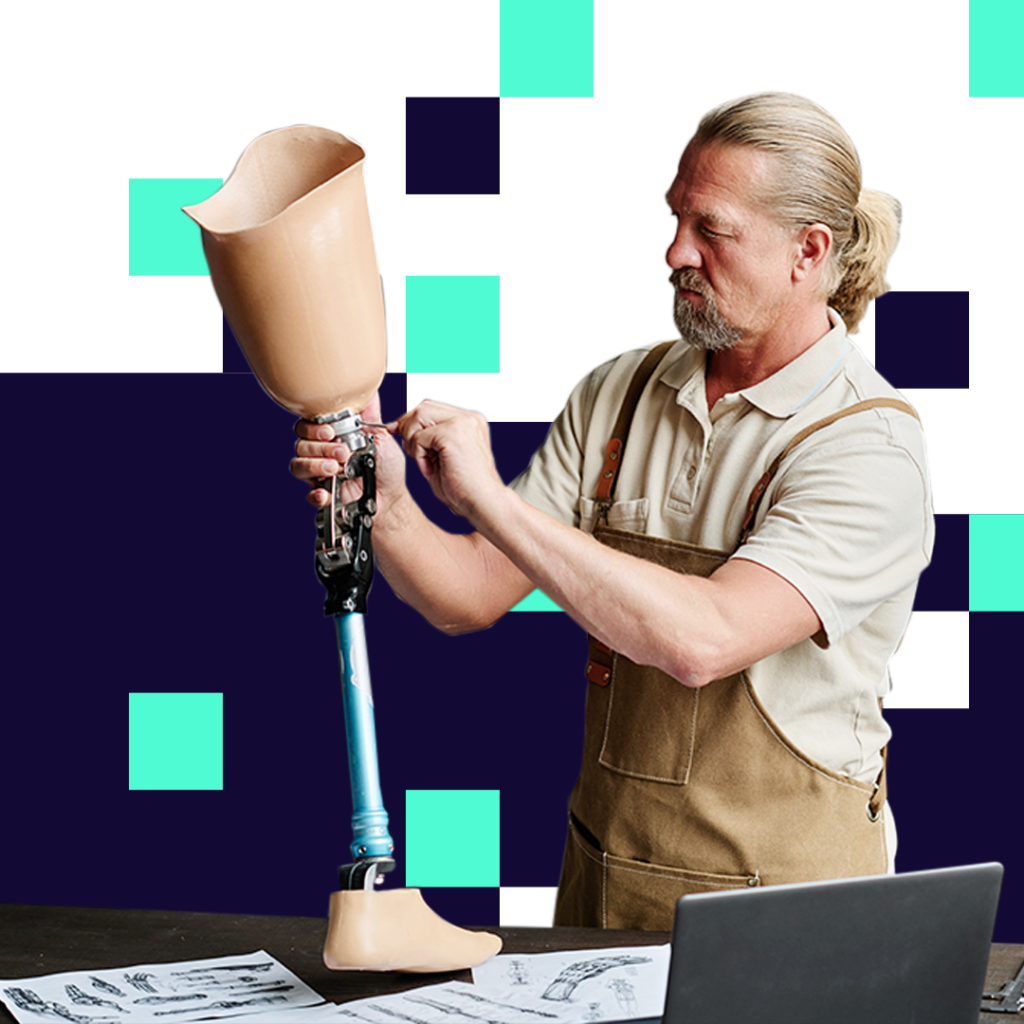

Understanding Prosthetic Socket Systems

The socket is the interface between your residual limb and your prosthetic. It's where all the forces get distributed, where your body connects to technology, where comfort either happens or doesn't.

Modern socket systems go far beyond basic fit. They adapt to volume changes throughout the day, manage pressure distribution intelligently, and integrate with advanced suspension systems to keep you stable and comfortable.

Types of Socket Systems

At Orthotics Limited, we offer multiple socket technologies. Each is designed for specific situations, activity levels, and residual limb characteristics.

Direct Socket System

Your definitive socket is fabricated directly on your limb in hours, not weeks. Real-time adjustments mean better initial fit. This eliminates the errors that can happen with traditional casting and molding. You walk in with a residual limb and walk out with a custom socket the same day.

Adjustable Socket Systems

Fine-tune your socket fit throughout the day using dial or strap adjustments. These systems compensate for limb volume changes from activity, temperature, and swelling. Your socket maintains optimal fit as your residual limb naturally changes.

Vacuum Socket Systems

Active or passive vacuum creates secure suspension between your socket and limb. This reduces limb volume fluctuations by up to 30% and promotes better circulation. Users report improved proprioceptive feedback and control. Available with pump units or one-way valve systems.

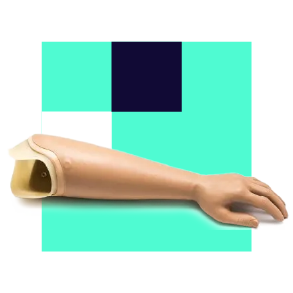

Total Surface Bearing (TSB) Sockets

Weight is distributed across your entire residual limb surface instead of concentrated on specific areas. Gel interface liners provide superior comfort. Ideal for those with scar tissue or sensitive skin. Lower trim lines improve mobility.

Hydrostatic Sockets

These sockets use consistent gel pressure to promote healthy tissue adaptation. They reduce pressure peaks and skin breakdown risk while providing better padding at the limb end. A variation of TSB design optimized for challenging residual limbs.

Ischial Containment Sockets

Designed for above-knee amputees. These sockets provide enhanced stability and control by encapsulating the ischium within the socket. Users gain increased hip range of motion and a more discreet appearance under clothing.

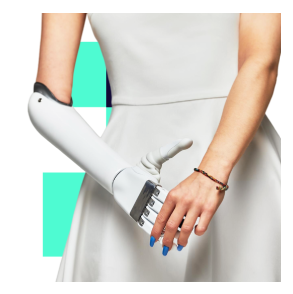

Realistic Silicone Covers

3D Printed Custom Covers

Foam Covers

Waterproof Covers

Laminating Sleeves

Why Us

The Why Behind Socket Technology

Live Without Pain

The right socket eliminates the constant discomfort that makes people give up on prosthetics. You shouldn't have to choose between mobility and pain. With proper fit, you can do both.

Stay Active All Day

Poor sockets force you to take breaks, sit down, or remove your prosthetic. Advanced socket systems let you stay active from morning to night without discomfort.

Avoid Skin Problems

Pressure sores, blisters, and skin breakdown aren't inevitable. Properly designed sockets distribute forces correctly and reduce friction, keeping your skin healthy.

Get Back to Your Life

Whether it's work, sports, or daily tasks, the right socket gives you back the confidence and physical ability to fully participate in life again.

Our Process

How We Create Your Custom Socket

Our approach is thorough and personalized. We don't rush the fitting process because getting it right matters more than getting it fast.

01

Assessment & Goal Setting

02

3D Scanning or Casting

03

Test Socket Fabrication

04

Socket Creation

05

Fitting & Alignment

06

Follow-Up & Adjustments

Testimonial

Success Stories from Our Clients

Robert K.,

Above-Knee Amputee

Michelle S.,

Below-Knee Amputee

James P.,

Below-Knee Amputee

Locations

Find a Prosthetics Clinic Near You

Your journey to better mobility starts with finding the right clinic for you. We have four locations, each offering personalized care, expert guidance, and a team dedicated to your well-being.

Find the nearest clinic and connect with us today.

Comprehensive prosthetics and orthotics

FAQs About Prosthetic Socket Systems

How long does it take to get a socket?

With our direct socket system, you can have a definitive socket the same day. Traditional custom sockets typically take 5-10 days from initial consultation to final fitting. We fabricate on-site, so we’re much faster than facilities that outsource.

How often will I need a new socket?

Most prosthetic users need socket replacement every 1-2 years. Factors include residual limb changes, weight fluctuations, and activity level. Adjustable sockets may extend this timeline by accommodating changes without full replacement.

What if my socket doesn't fit right?

We won’t send you home with an uncomfortable socket. Multiple test fittings and adjustments are built into our process. After you receive your final socket, we provide follow-up appointments and same-day adjustments if issues arise.

Can you work with difficult or complex residual limbs?

Yes. We specialize in challenging cases—short limbs, bony prominences, irregular shapes, extensive scarring, wounds. We have over 40 years of experience solving problems other prosthetists couldn’t handle.

What's the difference between a direct socket and a traditional socket?

Direct sockets are fabricated on your limb in real-time using modular components and a thermoforming process. Traditional sockets require casting, mold creation, and lamination. Direct sockets are faster and eliminate potential errors from the casting process.

Have more questions?

Your Socket Should Work

If it doesn’t, we’ll make one that does.

Schedule your consultation.